Thermal Interface Materials in LED Lighting Applications

28.08.2017Thermal interface material (TIM) is one of the important media between the base-plate of LED and the cooling system. Generally, higher thermal conductivity of TIM is better in heat dissipation. However, only considering the thermal conductivity may not be enough. In this article, we explain other important factors to consider when choosing proper TIM.

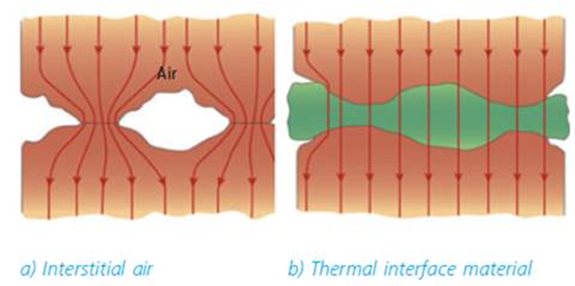

Thermal interface materials are those which are useful for establishing an effective thermal path between a heat source such as LED chip and a cooling system such as heat sink. Thermal interfacial materials (TIMs) are thermally conductive materials which are applied to increase thermal conductance across jointed solid surfaces, such as between the PCB and heat sink, in order to increase thermal transfer efficiency. The gaps in between surfaces in mechanical contact are filled with air, which is a very poor conductor (see Figure 1).

Figure 1. Air gabs between two surfaces: a - unfilled, b – filled by TIM

There are large variety of thermal interface materials, thermal grease, phase change materials, thermal tapes and gap filling thermal pads in the market. Many interface materials are comprised of a base material (e.g. grease or polymer) with added fillers (e.g. ceramic particles) to enhance the thermal conductivity relative to the base material.

PPI Adhesive Products develops range of thermal conductive films and self-adhesive tapes. These allow customers to achieve cost effective and high-quality solution to above described problem.

Some of the most favorite materials are these:

- PPI TC 150B-1000B - Thermally Conductive Double-Sided Foam Tapes

- PPI TCS 250B-100B - Thermally Conductive Single-Sided Foam Tapes

- PPI RD-548 - Transfer Acrylic Adhesive Thermally Conductive Tapes

- PPI RD-628 - High-Bond Double-Sided Adhesive Thermally Conductive Tapes

Furthermore, PPI converting and die-cutting capabilities benefit our customers with options of high level of automation in assembly process of LED and heatsink cooling system.

LED Performance and Lifetime Degradation

LED Lifespan:

One of the key problems that TIMs are helping to reduce is the shortening of LED module lifespan. High junction temperature (Tj) degrades LED performance, particularly its useful life, color quality and lumen output. Beyond the maximum rated junction temperature, the LED will experience a 30–50 % decrease in its useful life for every 10 °C increase.

Color shift problem:

The benefit of proper cooling are also important in maintaining the proper color temperatures of LED chip. Increase in junction temperature also creates a noticeable color shift toward the higher end of the spectrum. This is important with ‘white’ light LED sources that typically use blue wavelengths coupled with a phosphor. The heat causes a shift towards red wavelengths, the interaction with the phosphors is altered, resulting in a different hue of white light.

LED Efficacy:

Careful selection of quality TIMs can positively influence is LED lumen output. Increases in electrical current generally increases in lumen output. However, higher current also increases thermal build-up within the LED. Because of this, the current has to be adjusted in order to optimize system performance and useful life.

Some More Physics Behind All of This:

Thermal Conductivity - key parameter of thermal interface material Thermal conductivity is a material property and does not depend on the geometry of the sample. It is simply describes that ability of a given material to transfer heat through internal heat conduction.

Thermal resistance - Thermal resistance of material is an empirical property derived from analogy between electrical and thermal conduction. The heat transfer rate may be considered as a flow and the combination of thermal conductivity, thickness of material, and area as a resistance to this flow.

Junction temperature (Tj) - When driving the electrical current through the LEDs chip, a by-product of the emitted light production is heat. It is important to maintain the junction temperature of LED at the lowest possible value. The word ‘junction’ refers to the p-n junction inside the LED semiconductor die. You can find the maximum recommended value for each LED product in its datasheet. As Tj is the highest temperature within the LED, it represents a figure-of-merit when predicting LED lifetime. From a thermal point of view, junction temperature is affected by many factors such as the cooling system, environment and interface material, etc.

The equation for calculating junction temperature is expressed by:

Tj = Rj-c x P +Tc

Where Rj-c thermal resistance from the junction to the case which is supplied by the manufacturer, the thermal power, P – is electrical power of LED and Wall Plug Efficiency (WPE), and Tc the case temperature. If Tj is higher than the maximum allowable junction temperature which is specified by the manufacturer, the LED & heatsink cooling system has to be redesigned.

Other news

all newsSpotlight On: Milan Pančík - A Passion for an Active Lifestyle

Today we are happy to introduce another member of the PPI team - Milan Pančík, our sales manager for Slovakia, Hungary, Slovenia, Croatia, and Romania...

READ MOREFOCUS ON Copper

Copper, which represents elegance with its orange-red appeal, is admired for its conductivity and resilience. From ancient civilizat...

READ MORE